Reshaping Maintenance Strategies: The Convergence of IoT and AI

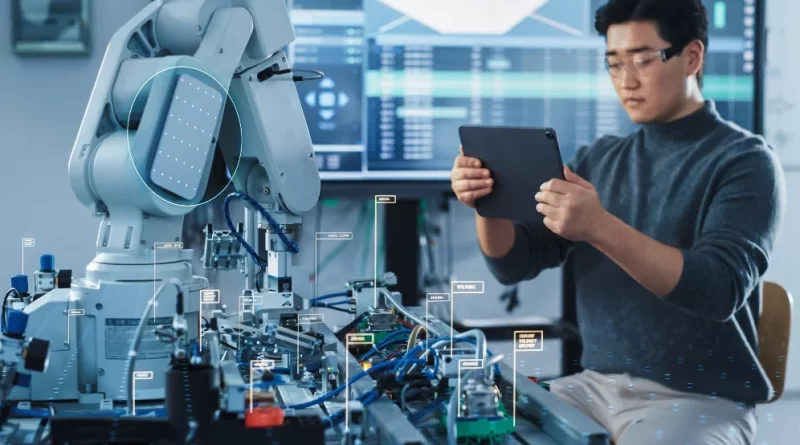

In today's competitive landscape, the convergence of IoT and AI technologies is reshaping maintenance strategies. By leveraging real-time data collection and AI-driven predictive techniques, organizations can optimize asset management, reduce costs, and enhance operational efficiency. This article explores the transformative potential of IoT and AI in driving proactive maintenance and revolutionizing the way businesses approach maintenance and asset management.

In today’s fast-paced and highly competitive business landscape, organizations are constantly seeking innovative approaches to optimize their operations and stay ahead of the curve. One area that has witnessed a significant transformation is maintenance strategies. With the convergence of the Internet of Things (IoT) and Artificial Intelligence (AI), businesses are leveraging these technologies to reshape predictive techniques and revolutionize the way they approach asset management. This article explores in depth how the integration of IoT and AI is driving the next frontier in maintenance, providing organizations with unprecedented insights, cost savings, and operational efficiency.

The Power of IoT-Enabled Data Collection and Analysis

At the core of IoT lies the ability to collect and analyze vast amounts of data from interconnected devices. This has opened up new possibilities for maintenance strategies, enabling organizations to make informed decisions based on real-time information. IoT-enabled devices, such as sensors and smart meters, have become integral components of modern maintenance practices. These devices continuously monitor equipment performance, capturing valuable data that can be leveraged for predictive maintenance.

By harnessing IoT-enabled data collection and analysis, businesses can move away from traditional reactive maintenance approaches and transition to proactive and predictive strategies. Instead of waiting for equipment failures to occur, organizations can leverage the wealth of real-time data to anticipate potential issues and take preventive action. This shift from reactive to proactive maintenance is a game-changer, as it minimizes downtime, reduces costs, and enhances overall operational efficiency.

Predictive Maintenance: Enhanced Accuracy through IoT

Predictive maintenance has long been recognized as a valuable technique for optimizing maintenance activities. However, the advent of IoT has significantly enhanced the accuracy and effectiveness of these methods. Traditional predictive maintenance techniques relied on historical data and manual analysis to anticipate equipment failures. While useful, these approaches were limited in their ability to provide real-time insights and accurate predictions.

With the introduction of IoT, organizations can now tap into a wealth of real-time data that enables more precise predictions. IoT-enabled devices continuously collect data on equipment performance, environmental conditions, and other relevant factors. This constant stream of data allows businesses to identify patterns, trends, and anomalies that may indicate impending equipment failure. By analyzing this data in real time, organizations can proactively schedule maintenance activities, minimizing downtime and reducing the likelihood of unexpected breakdowns.

AI-Powered Algorithms: Unleashing the Potential of Predictive Maintenance

While IoT enables the collection and analysis of vast amounts of data, it is Artificial Intelligence (AI) that unlocks the full potential of this data. AI-powered algorithms can process and interpret the complex data sets generated by IoT devices, identifying patterns, correlations, and anomalies that might go unnoticed by human analysts. This ability to uncover hidden insights and predict equipment failures with greater accuracy is transforming the field of predictive maintenance.

Machine learning, a subset of AI, plays a crucial role in enhancing the accuracy of predictive maintenance. By continuously learning from the data they process, AI algorithms become more proficient at identifying potential issues and predicting when they are likely to occur. As more data is fed into the system, the algorithms become increasingly accurate and reliable, making predictions that were previously impossible with traditional maintenance approaches.

A New Generation of Predictive Maintenance Solutions

The convergence of IoT and AI technologies has given rise to a new generation of predictive maintenance solutions that provide organizations with unprecedented levels of insight into their assets’ health. These solutions leverage the power of IoT-enabled data collection, analysis, and AI-driven algorithms to go beyond predicting equipment failures. They also enable businesses to identify the root causes of potential issues, allowing for proactive resolution before failures occur.

By implementing these advanced predictive maintenance solutions, organizations can achieve significant cost savings. Unplanned downtime, which can be costly and disruptive, is minimized as potential equipment failures are detected in advance. Moreover, by addressing issues proactively, organizations can extend the lifespan of their assets and avoid expensive emergency repairs or replacements. This not only reduces costs but also enhances operational efficiency and improves the overall performance of the organization.

Enhancing Safety and Environmental Performance

The integration of IoT and AI technologies in predictive maintenance solutions goes beyond cost savings and operational efficiency. It also has the potential to significantly enhance safety and environmental performance. By detecting potential equipment failures before they occur, organizations can prevent accidents and minimize the risk of environmental incidents, such as spills or emissions.

For example, in industries where equipment failure can lead to hazardous situations or environmental damage, early detection through IoT and AI technologies can be a game-changer. By promptly addressing potential issues, organizations can prevent accidents that may cause harm to employees, damage to infrastructure, or negative impacts on the environment. This not only helps businesses meet regulatory requirements but also safeguards their reputation and ensures the well-being of their employees and the communities in which they operate.

The Future of Maintenance: Predictive and Data-Driven

As the adoption of IoT and AI technologies continues to grow, the future of maintenance is set to become increasingly predictive and data-driven. Organizations that embrace these innovations can expect significant benefits in terms of cost savings, operational efficiency, and risk management. By leveraging the power of IoT-enabled data collection, analysis, and AI-driven algorithms, businesses can make more informed decisions, optimize maintenance strategies, and enhance overall performance.

However, to fully realize the potential of IoT and AI technologies in predictive maintenance, businesses must be prepared to invest in the necessary infrastructure and develop the skills required to harness these cutting-edge solutions. This includes establishing a robust IoT network, integrating data analytics capabilities, and training personnel in AI-driven maintenance techniques. By building these foundations, organizations can position themselves at the forefront of maintenance innovation and unlock the full potential of IoT and AI technologies.

The convergence of IoT and AI technologies is reshaping maintenance strategies, transforming the way organizations approach asset management. By leveraging IoT-enabled data collection and analysis, businesses can transition from reactive to proactive maintenance approaches. The integration of AI-powered algorithms enhances the accuracy of predictive maintenance techniques, allowing organizations to identify potential equipment failures with unparalleled precision. These advancements not only bring about cost savings and operational efficiency but also improved safety and environmental performance. As businesses embrace IoT and AI technologies, the future of maintenance will undoubtedly be predictive, data-driven, and filled with opportunities for innovation.